Our Automation Solutions

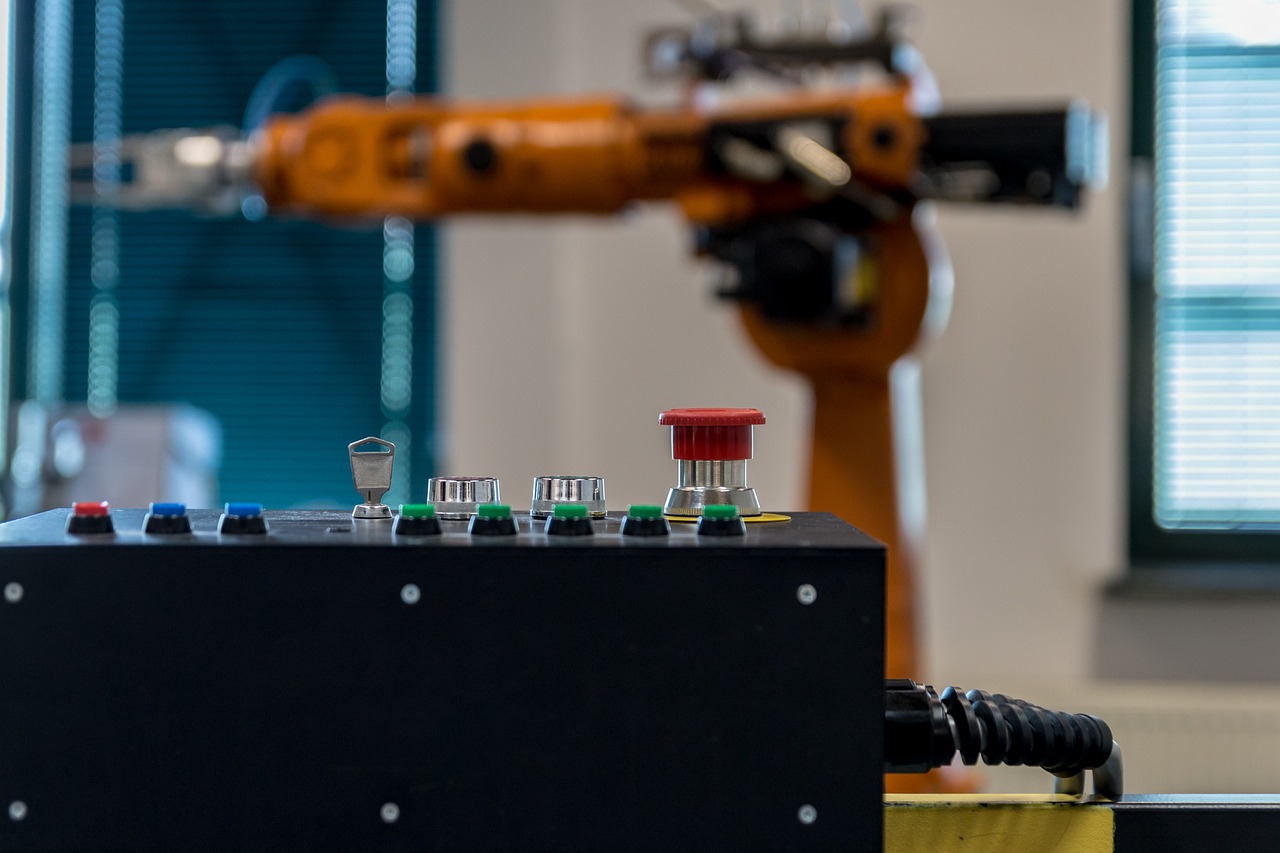

Robotic Process Automation

Streamline repetitive tasks with intelligent robotic automation that improves efficiency and reduces errors.

- Improved Efficiency: Automation significantly reduces the time required to complete repetitive tasks, ensuring faster operations and streamlined workflows.

- Enhanced Accuracy: By removing the possibility of human error, automated systems provide consistent and accurate results.

- Cost Savings: Automation reduces the need for manual labor, leading to long-term cost savings and optimized resource utilization.

- Scalability: Automated processes can handle increased production demands without additional costs.

- Employee Satisfaction: Free employees from mundane tasks, allowing them to focus on higher-value and more engaging work.

- Better Data Management: Collect and analyze data in real-time for improved decision-making.

- Improved Safety: In industries involving hazardous environments or materials, automation reduces risks by handling dangerous tasks, ensuring a safer workplace.

- Regulatory Compliance: Automated processes are easier to document and audit, helping companies stay compliant with industry regulations.

How Miracle Automation Helps:

- Customized Solutions: Miracle Automation specializes in understanding the unique needs of each client. We tailor automation solutions to fit your industry, ensuring a perfect match for your processes.

- End-to-End Support: From consultation and design to implementation and maintenance, we provide comprehensive support to ensure a smooth transition from manual to automated systems.

- State-of-the-Art Technology: Leveraging cutting-edge technologies like AI, IoT, and robotics, we deliver innovative solutions that maximize efficiency and precision.

- Industry Expertise: With experience across diverse industries, including manufacturing, healthcare, and logistics, Miracle Automation brings unparalleled expertise to every project.

- Future-Ready Designs: Our systems are scalable and adaptable, ensuring they meet both your current needs and future growth.

- Training and Integration: We offer training to your team and seamless integration with your existing processes to maximize the value of automation.

Research and Development

R&D is a critical driver for technological advancement and business growth, enabling companies to explore future opportunities and respond to industry trends effectively.

- Innovation and Competitive Advantage: R&D fosters creativity, enabling businesses to design innovative solutions that set them apart from competitors. It helps in creating unique products and processes that cater to unmet customer needs.

- Improved Efficiency: Through R&D, companies can streamline operations, enhance production efficiency, and reduce waste. It leads to the development of automated processes that save time and resources.

- Market Expansion: Companies can tap into new markets by developing products that cater to diverse industries and customer preferences. R&D allows adaptation to regulatory and cultural differences in international markets.

- Cost Reduction: Innovations in materials, processes, or technology can lower production costs without compromising quality. It reduces dependency on outdated, expensive methods and fosters sustainable practices.

- Problem-Solving:R&D enables companies to address industry-specific challenges through tailored solutions. It helps in solving critical issues such as safety, energy efficiency, and environmental sustainability.

- Customer Satisfaction:Understanding customer pain points through research helps in creating products that align closely with their needs. Continuous improvement of products and services boosts brand loyalty and reputation.

- Long-Term Growth: Companies with robust R&D programs are better prepared for the future, ensuring they remain relevant and profitable in a dynamic market. Patents and proprietary technologies developed through R&D create long-term intellectual property assets.

How Miracle Automation Helps:

- Custom Solutions Development: Analyze the specific challenges faced by industries such as manufacturing, healthcare, and logistics. Design and develop tailored automation solutions, such as specialized robotic systems or custom software.

- Innovation in Automation: Invest in advanced technologies like AI, IoT, and machine learning to improve robotic capabilities and decision-making. Research new materials and methods for creating durable, efficient, and sustainable automation equipment.

- Prototyping and Testing: Build and test prototypes of innovative products, such as next-generation robotic arms or automated assembly lines. Use advanced simulation tools to analyze performance and optimize designs before full-scale production.

- Collaboration with Academia and Industry: Partner with universities, research institutions, and industry leaders to explore new technologies and methodologies. Collaborate on projects that push the boundaries of automation and robotics.

- Sustainability Initiatives: Research eco-friendly processes and materials to create energy-efficient and environmentally sustainable solutions. Develop automation systems that reduce waste, minimize emissions, and align with global sustainability goals.

- Process Optimization: Conduct studies to identify inefficiencies in existing systems and design solutions to overcome them. Implement real-time monitoring and predictive maintenance through IoT-enabled devices.

- Niche Markets: Research the needs of untapped markets and design automation systems tailored to specific regional industries. Develop solutions for niche industries, such as agriculture (e.g., precision farming automation) or healthcare (e.g., robotic surgical assistants).

- Fostering Intellectual Property: Focus on patenting new technologies and methodologies developed through R&D. Create proprietary systems that provide a competitive edge and protect against market imitation.

AI Insights

AI Insights are invaluable in helping businesses become more efficient, innovative, and customer-focused.

- Data-Driven Decision-Making: AI can process massive datasets to identify patterns and trends that are impossible for humans to detect manually. Businesses can make more informed, accurate, and timely decisions based on predictive analytics.

- Enhanced Efficiency: By automating repetitive tasks and identifying bottlenecks, AI insights help optimize workflows and reduce operational costs.

- Personalized Experiences: AI can analyze behavior and preferences, enabling businesses to tailor their services and products for individual needs.

- Risk Mitigation: AI systems can detect anomalies, fraud, or cybersecurity threats in real-time, protecting businesses from potential losses.

- Innovation Enablement: Insights from AI can fuel innovation by uncovering opportunities for new products, services, or process improvements.

- Scalability: AI systems can handle large-scale operations, enabling businesses to scale efficiently without a proportional increase in resources.

How Miracle Automation Helps:

- Predictive Mainenance: Use AI to monitor equipment performance and predict failures before they occur, minimizing downtime and repair costs.

- Optimization of Manufacturing Processes: AI-driven insights can be used to monitor and optimize factory floor operations, reducing downtime and improving throughput.

- Material and Process Innovation: Use AI insights to explore new materials or manufacturing techniques, ensuring better performance and reduced costs.

- Data Analytics as a Service: Provide analytics services powered by AI, helping clients make data-driven decisions across operations, supply chain, and customer engagement.

- Prototype Testing and Simulation: Utilize AI for virtual testing and simulations, reducing time and costs associated with physical prototyping.

Smart Manufacturing

Smart manufacturing goes beyond automating production; it focuses on designing and upgrading manufacturing machines to be more intelligent, adaptable, and efficient in increasing output. This involves integrating sensors, enabling automatic movement of products between stations, identifying defects, and separating quality products from faulty ones.

- Increased Efficiency and Productivity: Automated workflows enhance production speeds while maintaining high precision and quality.

- Cost Reduction: Optimized resource allocation and minimized waste lower operational costs.

- Enhanced Flexibility and Scalability: Smart manufacturing systems can adapt to changing demands and support customized production runs with minimal reconfiguration.

- Sustainability: Smart manufacturing reduces energy consumption, waste, and emissions through precise resource utilization and monitoring.

- Worker Safety and Collaboration: IoT-enabled devices and robotics take over hazardous tasks, creating safer work environments. Collaborative robots (cobots) enhance human-machine interaction for increased productivity.

- Supply Chain Optimization: Smart factories enable just-in-time inventory and seamless supply chain management.

How Miracle Automation Helps:

- Designing Intelligent Manufacturing Machines: Develop machines equipped with advanced sensors for decision-making and real-time monitoring.

- Retrofitting Existing Equipment: Upgrade legacy machinery by integrating modern control systems for better adaptability and efficiency.

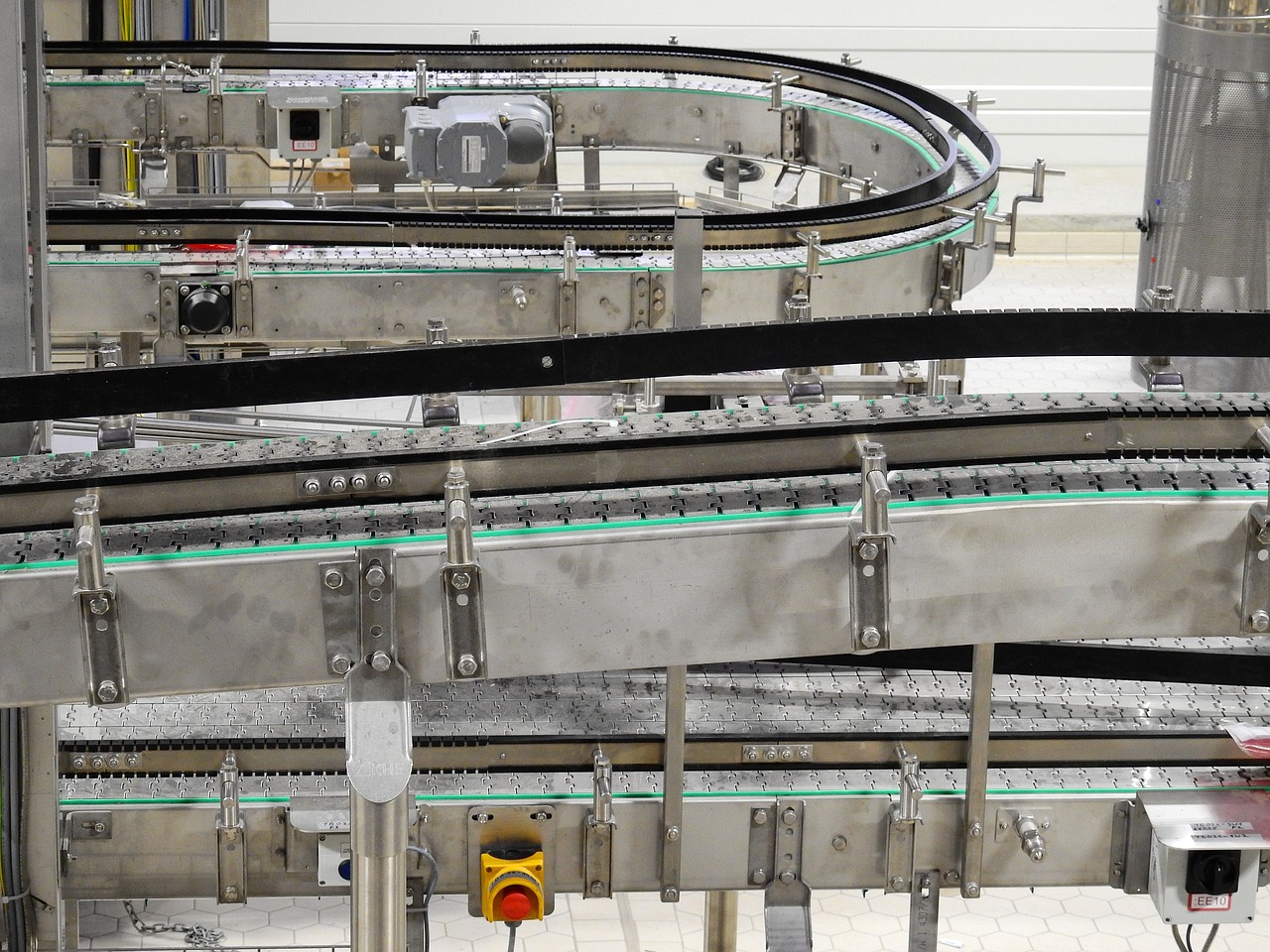

- Custom Automation Solutions: Design and deploy bespoke automation systems tailored to specific manufacturing needs, including robotics, conveyor systems with advanced sensors.

- Collaborative Robotics: Design and integrate cobots that work alongside human operators to improve safety, efficiency, and throughput.

- Advanced Quality Control: Use machine vision and AI for automated inspection systems that detect defects and maintain high product standards.

Quality Inspection and Control

Quality Inspection and Control is a critical part of manufacturing and delivery to ensure that products, materials, or services meet specified quality standards.

- Improved Product Quality: Ensures that products consistently meet or exceed customer expectations, enhancing customer satisfaction and brand reputation.

- Cost Reduction: Early detection of defects prevents costly rework, waste, and recalls, saving resources and time.

- Regulatory Compliance: Helps meet industry standards and legal requirements, avoiding fines, recalls, or legal liabilities.

- Enhanced Customer Trust: Consistent quality builds confidence among customers and stakeholders, leading to increased loyalty and repeat business.

- Risk Mitigation: Identifies and addresses potential issues in production or supply chains, reducing the likelihood of failure or downtime.

- Competitive Advantage: A strong commitment to quality differentiates businesses in competitive markets, attracting more customers.

How Miracle Automation Helps:

- Automated Quality Inspection Systems: Develop and deploy systems that use advanced technologies such as machine vision and IoT sensors to detect defects and anomalies in real-time. Examples include systems for surface defect detection, dimensional accuracy verification, and material integrity testing.

- Robotic Inspection:Deploy robots equipped with cameras and sensors to inspect hard-to-reach areas or repetitive tasks with high precision and speed.

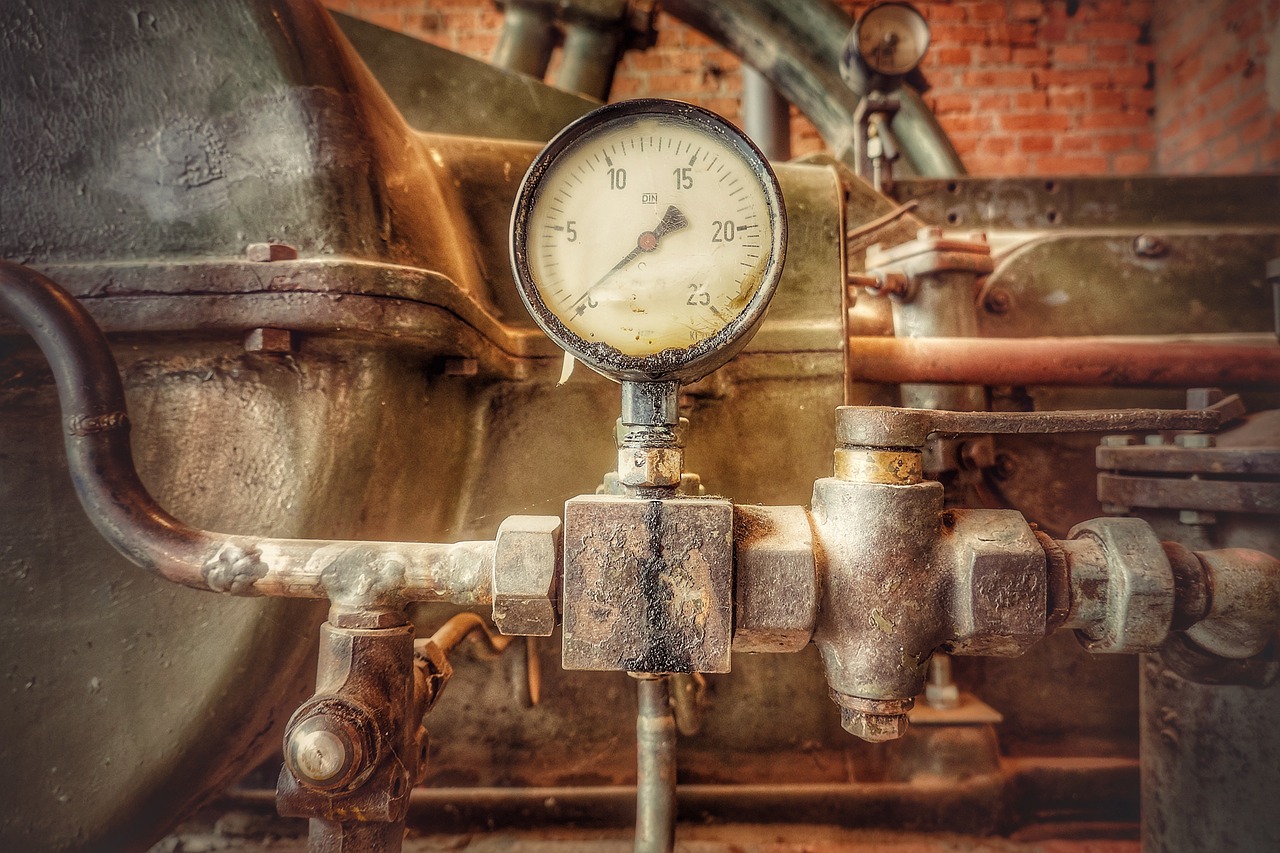

- IoT-Enabled Quality Monitoring: Utilize IoT devices to continuously monitor production parameters like temperature, pressure, and humidity, ensuring optimal conditions for quality production.

- Integration with Manufacturing Processes: Design solutions that integrate quality control checkpoints into manufacturing lines, enabling real-time feedback and immediate corrections.

- 3D Scanning and Metrology Solutions: Develop 3D scanning systems for precise dimensional measurements and ensure compliance with design specifications.

- Data Analytics for Continuous Improvement: Provide analytics dashboards that aggregate quality inspection data, allowing manufacturers to identify trends and make informed decisions for process improvements.

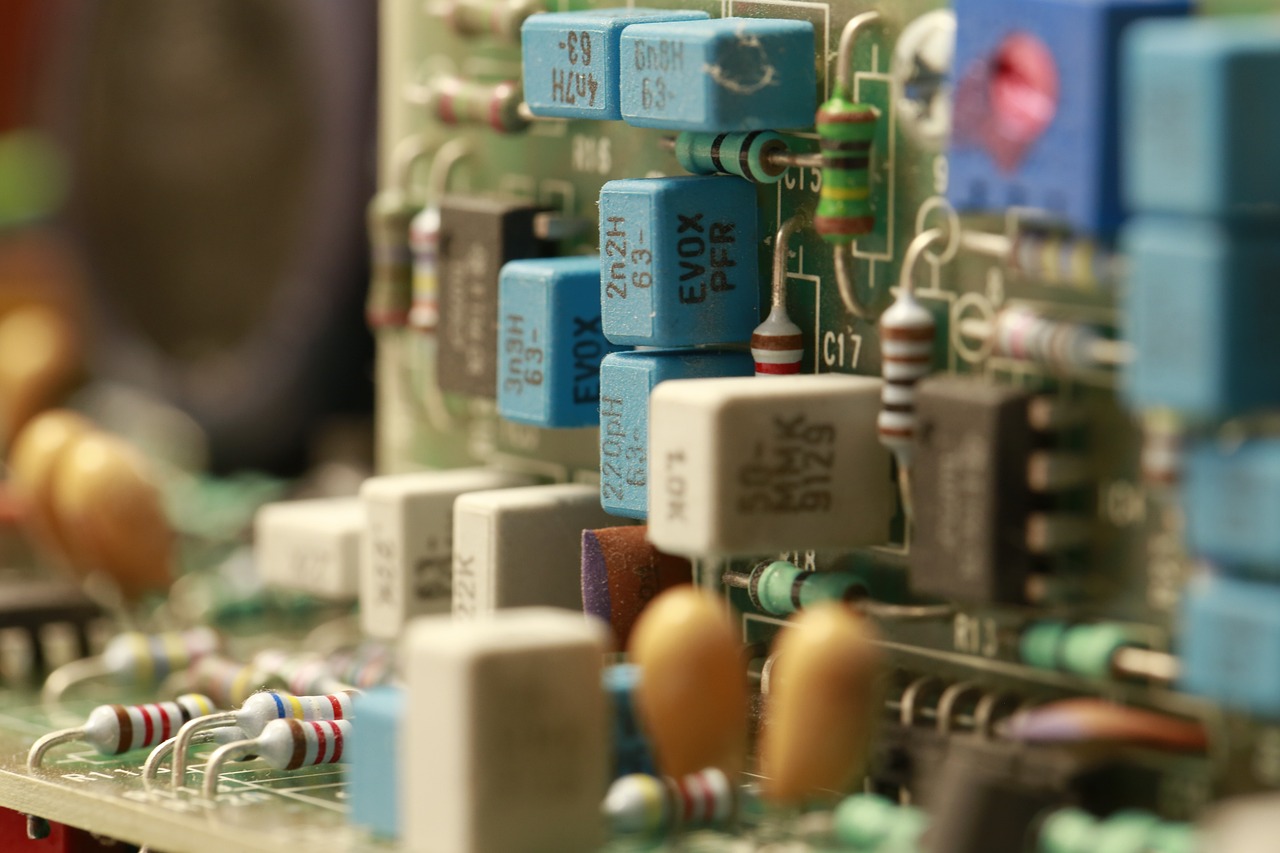

- Custom Solutions for Specific Industries: Create tailored solutions for industries such as automotive, aerospace, and electronics, where precision and compliance are critical. For example, laser-based inspection systems for weld quality or high-speed cameras for PCB assembly checks.

- Non-Destructive Testing (NDT): Offer systems for non-destructive testing, such as ultrasonic or X-ray inspection, ensuring the integrity of products without causing damage.

- Training and Maintenance: Provide training to client teams on quality control technologies and ensure long-term support with regular system maintenance and updates

- Standardization and Compliance: Help businesses meet ISO and other regulatory standards by automating compliance documentation and reporting.

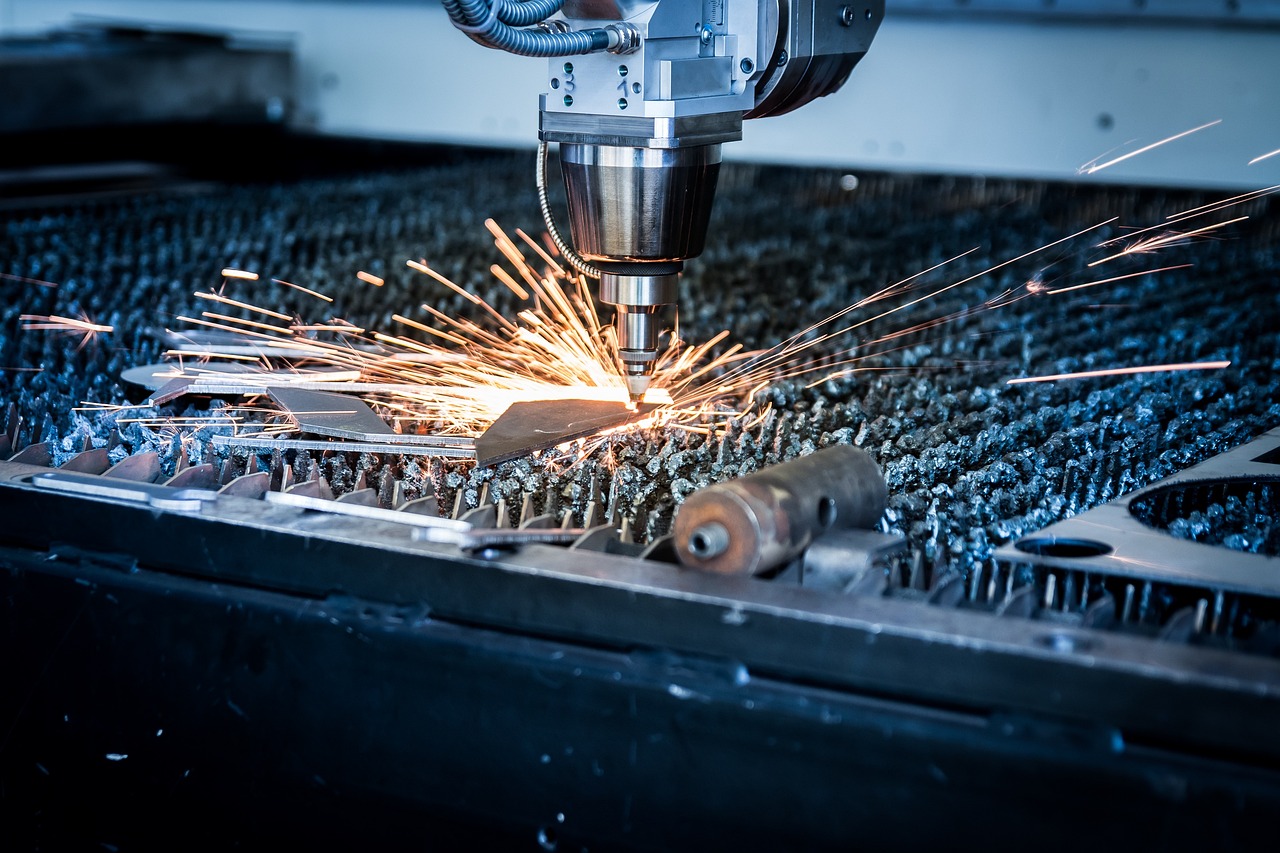

Laser Systems

Laser Systems harness concentrated light energy to perform tasks with extreme accuracy for cutting, welding, engraving and marking

- High Precision: Lasers provide exceptional accuracy, enabling operations on tiny or intricate components without damaging surrounding materials.

- Speed and Efficiency: Laser systems can complete tasks much faster than traditional methods, reducing production time and increasing throughput.

- Versatility: Lasers can work with a wide range of materials, including metals, plastics, glass and ceramics.

- Non-Contact Process: The non-contact nature of lasers minimizes wear and tear on tools, reducing maintenance costs and ensuring longer equipment life

- Enhanced Quality: Laser processes produce cleaner edges, finer details, and minimal material distortion, improving the overall quality of the finished product.

- Cost-Effectiveness: Reduced waste, fewer consumables, and minimal need for post-processing make laser systems economically advantageous.

- Automation Compatibility: Laser systems integrate seamlessly into automated production lines, enabling smarter and more efficient workflows.

- Environmental Benefits: Lasers generate less waste and consume fewer resources compared to traditional manufacturing methods, making them more eco-friendly.

How Miracle Automation Helps:

- Customized Laser Solutions: Develop tailor-made laser cutting, welding, or engraving systems to meet the specific needs of clients in industries like automotive, aerospace, and healthcare.

- Laser Cutting Systems: Provide high-precision cutting systems for materials like metals, plastics, and composites, catering to applications in electronics, medical devices, and construction.

- Laser Welding: Implement laser welding solutions for industries requiring strong, high-quality joints, such as automotive chassis manufacturing or aerospace components.

- Laser Engraving and Marking: Offer laser engraving systems for high-speed, permanent marking of serial numbers, logos, or QR codes on products.

- Laser-Based Measurement and Inspection: Develop systems for dimensional measurement, surface inspection, or quality control using lasers, ensuring manufacturing accuracy.

- Integration with Robotics: Combine laser systems with robotic arms to create fully automated, flexible workstations for tasks like welding, cutting, and assembly.

- Training and Support: Provide end-to-end services, including system design, installation, training, and ongoing maintenance, ensuring clients maximize the value of their laser systems.

- Industry-Specific Solutions: Collaborate with clients to develop solutions tailored to their specific industries, such as intricate surgical tools in healthcare or lightweight structures in aerospace.

Endurance Test Bench

Endurance Test Bench is a specialized testing platform designed to evaluate the durability, performance, and reliability of mechanical, electrical, or automated components under prolonged operating conditions. This bench simulates real-world stressors, including repetitive motions, environmental conditions, load cycles, and extreme scenarios, to ensure a product meets expected life cycles and withstands operational demands. Endurance test benches are critical in industries such as automotive, aerospace, robotics, and manufacturing, where product reliability directly impacts safety, performance, and brand reputation.

- Product Reliability and Safety: Ensures products can withstand prolonged use without failure, reducing risks associated with breakdowns or malfunctions. Identifies weak points in the design that could compromise safety or performance.

- Performance Validation: Tests components to ensure they perform optimally under a variety of real-world conditions.

- Quality Assurance: Demonstrates compliance with industry standards and customer expectations for durability and robustness. Builds customer trust by guaranteeing long-term performance.

- Cost Savings: Prevents costly product recalls or warranty claims by identifying issues during development. Reduces long-term maintenance and operational costs for clients by ensuring durable products.

- Optimized Design: Provides critical feedback for iterative design improvements, ensuring more efficient and effective products.

- Testing under Extreme Conditions: Simulates challenging conditions like extreme temperatures, high loads, or continuous operation cycles to ensure the product performs under stress.

- Market Differentiation:Demonstrating superior product endurance can serve as a competitive advantage, particularly in markets where durability is a key selling point.

How Miracle Automation Helps:

- Development of Tailored Test Benches: Design and develop custom endurance test benches for clients across various industries including automotive, manufacturing, and consumer goods, tailored to specific products or components.

- Advanced Testing Services: Offer endurance testing as a service for clients who need to validate the reliability of their products without investing in their own test bench infrastructure.

- Integration of IoT and AI: Build test benches integrated with IoT sensors to collect real-time performance data and AI systems to analyze the results, providing actionable insights for clients.

- Simulation of Harsh Environments: Create test benches that replicate extreme conditions, such as high temperatures, humidity, vibrations, or repetitive mechanical stresses.

- Prototyping and Validation: Use endurance test benches during prototyping to identify design flaws early in the development process, reducing costs and time-to-market.

- Data-Driven R&D: Use the insights gathered from endurance testing to innovate new materials, designs, and manufacturing processes for more robust products.

- Customized Reporting: Deliver detailed reports on endurance test results, offering clients insights into performance, failure points, and improvement recommendations.

- Client Training and Support: Provide training to clients on how to use the test bench effectively and interpret the data to improve their product designs.

Monitoring Services

Monitoring Services refer to the continuous observation and assessment of systems, processes, or environments to ensure optimal performance, identify anomalies, and address issues proactively. These services leverage tools and technologies to track real-time metrics, analyze trends, and trigger alerts or actions when specific thresholds or conditions are met. Monitoring services are widely used in manufacturing, infrastructure, and automation industries to maintain operational excellence, enhance safety & security, and reduce downtime.

- Improved Operational Efficiency: Continuous monitoring ensures that systems and processes run at optimal levels, preventing inefficiencies and delays.

- Proactive Issue Resolution: Detect anomalies or potential problems before they escalate into critical failures, minimizing downtime and disruptions.

- Enhanced Safety & Security: Monitoring services help identify safety issues with breakdowns, unauthorized access, or suspicious activities in real-time, enabling swift corrective actions.

- Cost Savings: By preventing unexpected failures and optimizing resource usage, monitoring reduces maintenance and operational costs.

- Data-Driven Insights: Collect and analyze data to identify patterns, trends, and opportunities for process improvement.

- Compliance and Reporting: Ensure regulatory compliance by monitoring and logging activities, which can be useful during audits or reviews.

- Scalability: Monitoring services scale effortlessly with growing operations, ensuring all systems remain under observation without additional overhead.

- Customer Satisfaction: Proactively addressing issues leads to improved reliability and customer trust, enhancing satisfaction and loyalty.

How Miracle Automation Helps:

- Real-Time Monitoring Systems: Develop and deploy tools for real-time tracking of robotic systems, manufacturing equipment, and automation processes. Provide centralized dashboards to monitor KPIs (Key Performance Indicators) across operations.

- Predictive Maintenance Solutions: Use monitoring data combined with various models to predict equipment failures, allowing preemptive maintenance and reducing downtime.

- Energy and Resource Monitoring: Develop systems to track energy consumption, material usage, and other resources, enabling optimization and sustainability efforts.

- Alerts and Notifications: Design systems that send automated alerts (via email, SMS, or app) when predefined conditions are met, ensuring quick action.

- Compliance Monitoring: Develop solutions to ensure compliance with industry standards by continuously monitoring critical metrics and generating automated reports.

- Training and Support: Provide training to clients' teams on using monitoring systems effectively and offer 24/7 support for troubleshooting and system enhancements.

- Integration Services: Integrate monitoring tools with existing enterprise systems (ERP, CRM, or MES) for seamless operations.

After Market Care

After Market Care refers to all the services, support, and activities provided to customers after a automation product has been sold or deployed. This includes maintenance, repairs, spare parts supply, upgrades, customer support, training, and end-of-life recycling.

- Extended Product Lifecycle: Regular maintenance and timely upgrades ensure the product stays functional and relevant for a longer period, maximizing ROI.

- Reduced Downtime: Quick and efficient repair and maintenance services help customers minimize operational disruptions, which is critical for industrial clients.

- Environmental Responsibility: Recycling, refurbishing, and proper disposal services reflect a commitment to sustainability, appealing to environmentally conscious customers.

How Miracle Automation Helps:

- Comprehensive Maintenance Programs: Offer preventive and predictive maintenance services to ensure customers' systems run smoothly and avoid costly breakdowns.

- Customer Support Support team to address customer concerns and technical issues ensuring minimal downtime.

- Spare Parts Management: Establish a supply chain for spare parts with fast delivery to ensure customers can quickly replace worn or faulty components

- Upgrades and Modernization: Provide upgrade kits or retrofitting services to enhance the performance and functionality of older equipment.

- Remote Monitoring and Diagnostics: Implement IoT-enabled systems to remotely monitor customer equipment, diagnose problems in real time, and offer proactive solutions.

- Extended Warranties: Offer extended warranty plans that cover repairs and replacements, providing peace of mind to customers.

- Recycling and Refurbishing Programs: Programs for recycling old parts or refurbishing equipment, contributing to sustainability.

- Field Service Teams: Deploy skilled technicians for on-site repairs, maintenance, and training, ensuring quick response times and excellent service.

Energy-Efficient Automation

Energy-efficient automation refers to designing, implementing, and optimizing automated systems and processes that consume minimal energy while maintaining or improving productivity. This approach ensures operations are both cost-effective and environmentally sustainable, aligning with global initiatives to reduce carbon footprints and achieve energy efficiency.

- Reduced Energy Costs: By optimizing energy consumption, businesses can significantly cut down on utility expenses.

- Environmental Sustainability: Lower energy usage reduces greenhouse gas emissions, helping companies align with environmental regulations and goals.

- Increased Operational Efficiency: Energy-efficient systems often operate more smoothly, reducing waste and improving overall productivity.

- Compliance with Regulations: Many industries are subject to energy and emissions regulations. Energy-efficient automation helps meet these requirements, avoiding penalties.

- Enhanced Equipment Lifespan: Optimized energy usage reduces wear and tear on equipment, extending its operational life and reducing maintenance costs.

- Improved Corporate Image: Companies adopting energy-efficient solutions enhance their reputation as environmentally responsible organizations.

How Miracle Automation Helps:

- Designing Energy-Efficient Systems: Develop automation solutions that incorporate energy-efficient technologies such as variable frequency drives (VFDs), energy-efficient motors, and smart sensors. Optimize system designs to minimize idle time and eliminate redundant processes.

- Smart IoT Integration: Deploy IoT-enabled devices that monitor energy consumption in real-time and adjust processes to maximize efficiency.

- Optimizing Factory Layouts: Redesign production floors to reduce energy waste caused by inefficient layouts and workflows.

- Client Energy Audits and Recommendations: Offer energy audits for client operations and recommend automation upgrades to improve energy efficiency.

- Retrofitting Existing Systems: Provide solutions to retrofit older equipment with energy-efficient components, reducing the need for complete system overhauls.

- Custom Reporting and Dashboards: Develop dashboards that provide clients with insights into energy consumption and highlight areas for improvement.

Automated Material Handling

Automated Material Handling (AMH) refers to the use of automated systems and technology to transport, store, retrieve, and manage materials in warehouses, manufacturing facilities, and distribution centers. These systems include robotics, conveyor belts, automated guided vehicles (AGVs), automated storage and retrieval systems (ASRS), and other machinery that reduces the need for manual intervention. The goal of AMH is to streamline operations, improve efficiency, and reduce costs in managing the movement of goods and materials.

- Increased Efficiency: Automated systems can move materials faster and more consistently than manual labor, improving overall throughput and productivity.

- Reduced Labor Costs: By automating repetitive tasks, businesses can significantly reduce dependency on manual labor, resulting in long-term cost savings.

- Improved Accuracy: Automation minimizes human error in sorting, retrieving, or transporting materials, ensuring accuracy in inventory management and order fulfillment.

- Enhanced Safety: Automated systems reduce the risk of workplace injuries by handling heavy loads, hazardous materials, or dangerous tasks.

- Scalability: Automated systems can easily scale with business growth, accommodating higher volumes of materials without additional labor costs.

- Sustainability: Automation can optimize energy usage and reduce waste, contributing to environmentally sustainable operations.

How Miracle Automation Helps:

- Design and Deploy Customized AMH Solutions: Develop tailored solutions for warehouses, factories, and distribution centers based on specific material handling needs. Incorporate AGVs, ASRS, and conveyor systems for seamless material flow.

- Automated Sorting and Packaging Systems: Implement robotic arms and conveyor systems to automate sorting and packaging processes, ensuring faster and error-free operations.

- Warehouse Automation: Install ASRS to automate storage and retrieval processes, reducing downtime and improving space utilization. Use automated inventory systems for efficient stock management.

- Safety Solutions: Implement safety systems, such as sensors and collision avoidance technologies, in automated material handling equipment to ensure worker safety.

- Consulting and Training: Provide consulting services to analyze existing workflows and recommend AMH solutions. Train employees to use and manage automated systems effectively.

Supply Chain Automation

Supply Chain Automation involves automating repetitive tasks, improving data visibility, enhancing collaboration, and reducing human intervention across the supply chain

- Increased Efficiency: Automating repetitive tasks, such as inventory updates and order processing, reduces manual workload and accelerates operations. Faster turnaround times in warehousing and logistics due to robotic and automated systems.

- Improved Accuracy: Automation minimizes human errors in areas like data entry, inventory tracking, and order fulfillment.

- Cost Savings: Reduced labor costs by automating tasks like packing, sorting, and transportation planning. Optimized inventory and logistics operations lower operational expenses.

- Real-Time Visibility: Enhances decision-making by providing actionable insights through centralized dashboards.

How Miracle Automation Helps:

- Automated Warehouse Management: Implement robotics for tasks like picking, packing, and sorting to improve warehouse efficiency.

- Predictive Analytics for Demand Forecasting: Prevent supply chain disruptions by forecasting potential bottlenecks.

- Smart Warehousing Solutions: Develop smart warehouses with automated guided vehicles (AGVs) and robotic arms for handling goods. Enable clients to control and monitor warehouse activities remotely through IoT and AI.

- Custom Automation for Industry-Specific Needs: Tailor automation solutions for industries like healthcare, manufacturing, or retail to address their unique supply chain challenges. For example, automating cold chain logistics for pharmaceutical companies or implementing just-in-time (JIT) systems for manufacturers.

IoT Solutions

The Internet of Things (IoT) refers to a network of interconnected devices that communicate and exchange data with each other over the internet. These devices include sensors, machinery, appliances, and even vehicles, which are embedded with electronics, software, and connectivity features. IoT enables these devices to collect, share, and act on data, often autonomously, to enhance efficiency, functionality, and decision-making in various environments. Connect and optimize your operations with our IoT-enabled automation systems.

- Real-Time Data Collection and Monitoring: IoT devices gather data in real-time, enabling businesses to monitor processes, equipment, or customer behavior with high accuracy.

- Improved Efficiency: Automation of repetitive or manual tasks through IoT reduces human effort, streamlines workflows, and minimizes errors.

- Predictive Maintenance: Sensors can monitor equipment conditions and predict potential failures, minimizing downtime and reducing repair costs.

- Cost Reduction: By improving operational efficiency, reducing waste, and optimizing resource use, IoT significantly cuts costs in the long run.

- Scalability: IoT systems can be easily scaled up to handle more devices or operations as a business grows, making it a future-proof investment.

- Better Safety and Compliance: IoT devices can monitor hazardous environments, enforce safety protocols, and ensure compliance with industry regulations.

How Miracle Automation Helps:

- IoT-Enabled Manufacturing: Implement smart factories that use IoT sensors to monitor production lines, optimize machinery usage, and reduce waste. Develop predictive maintenance systems for industrial equipment.

- Smart Automation Solutions: Design IoT-powered automation systems for clients, such as robotic process automation integrated with real-time sensor data. Create IoT-based logistics solutions for inventory tracking and supply chain optimization.

- Connected Robotics: Build robots equipped with IoT sensors for seamless integration into industrial processes. These robots can adapt based on live feedback from their environment.

- Remote Monitoring and Control: Provide clients with remote monitoring capabilities for their equipment or processes, enabling them to oversee operations from anywhere.

- Custom IoT Dashboards: Create user-friendly dashboards that allow clients to visualize and act on IoT data, improving decision-making.

- Smart Asset Tracking: Use IoT to monitor the location and condition of assets in real-time, reducing losses and improving operational efficiency.